- Bargain Basement

- Abrasive Blasting

- Adhesion

- Ambient Conditions

- Cases

- Cathodic Protection

- Coating Test Panels

- Coating Thickness Gauge

- Combination Gauges

- Compliance Programs

- Concrete Testing

- Corrosion Coupon Test Kits

- Dry Film Thickness Gauges

- Field Microscopes

- Gloss & Appearance

- Hardness Testing

- Holiday/Pinhole Detection

- Inspection Instrument Kits

- Miscellaneous

- Moisture Detection

- Powder Coating

- Publications

- Surface Cleanliness

- Surface Contamination Test Kits

- Surface Profile

- Wall Thickness Gauges

- Wet Film Thickness Gauges

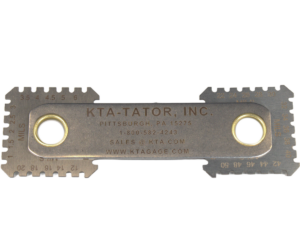

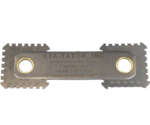

KTA-Tator Certified Stainless Steel Wet Film Thickness Gauge

$79.99

KTA Tator Wet Film Thickness Gauge reads both mills and microns. This revolutionary Gauge will change they way you measure WFT.

In stock (can be backordered)

SKU:

525252

Categories: Best Sellers, Coating Thickness Gauge, Wet Film Thickness Gauges

Tags: wet film thickness, wet mil gauge, wft, wft gauge

Description

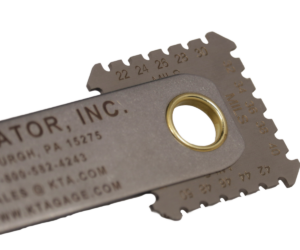

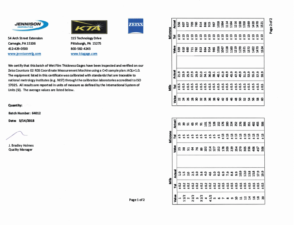

The KTA-Tator certified stainless steel wet film thickness gauge or wft gauge replaces 4 gauges needed to perform the same range. The patent-pending dual-head design allows 0-60 mils of coating to be measured and converted to microns (0-1524) by just flipping the gauge over. 5 measurement points per head allow more precision than competing equipment in the same form factor. Each wet film thickness gauge comes with a unique ID number and certificate of conformance at no additional cost. Also included is a carrying pouch. Each gauge conforms to ASTM D4414.

Gauge Usage:

The usage of these WFT gauges is straightforward. Each one of the faces is going to have a different range so initially select one that fits the amount of coating applied, as this will reduce the time it takes to get your reading.

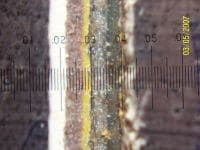

Immediately after the coating has been applied insert the measuring face that you selected into the wet coating. When inserting the wet film gauge make sure that the two end teeth are pushed all the way into the previous layer or the substrate (if you are on your first layer) at a 90° angle.

You are then going to want to remove the wet mil gauge from the coating. After removing look at the numbered notches, on the side that you inserted into the coating. The two stabilization teeth should have paint on them. If all the numbered notches have paint on the ends you are going to want to move to a higher head. If none of the numbered notches have paint on them, you will want to move to a lower head. Your wet film thickness will be the last notch of the wet film gauge that has paint on it.

Additional information

| Weight | .25 lbs |

|---|---|

| Brand |

KTA Tator |

| Build Material |

Stainless Steel |

| Test Method |

ASTM D4414 |

You may also like…

DeFelsko PosiTector 6000 and Probes

$325.00 – $1,865.00

DeFelsko Certified Coating Thickness Standards

$385.00

Certified coated metal plates are ideal for verifying the accuracy and operation of coating thickness gauges and are an important component in fulfilling both ISO and in-house quality control requirements.

Many organizations require verification of gauge accuracy at the test site each time a coating thickness gauge is put into service and at frequent intervals during use. Ideal for this purpose, DeFelsko certified coating thickness standards have measured values traceable to a National Metrology Institution. FERROUS

S1 0, 3, 10, 60 mils

S2 0, 3, 10, 40 mils

Select optionsEarn up to 19 points.

This product has multiple variants. The options may be chosen on the product page

KTA Aluminum Wet Film Thickness Gauge (25 Pack)

$45.00

Related products

PosiTector RTR Replica Tape Reader

$425.00 – $1,200.00

This remarkable digital spring micrometer measures and records average peak to valley surface profile height with improved accuracy us Testex Press-O-Film Replica Tape. It also provides inspectors with a digital record of measurements that can be downloaded to your computer.

Select optionsEarn up to 60 points.

This product has multiple variants. The options may be chosen on the product page

PosiTector 200 Ultrasonic Coating Thickness Gauge

$1,795.00 – $2,970.00

The PosiTector 200 Ultrasonic Coating Thickness Gauge measures the thickness of coatings over concrete, wood, composite materials, and more.

B-Probe for coatings over wood, composites. 0-40 mils.

C-Probe for coatings over concrete, fiberglass. 2-150 mils.

D-Probe for Thick soft coatings, polyureas, thick polymers. 2-300 mils.

Select optionsEarn up to 149 points.

This product has multiple variants. The options may be chosen on the product page

Positector IRT Probe

$195.00

PosiTest DFT All Metals Coating Thickness Gage

$695.00

Tooke Gauge

$75.00 – $1,380.00

Byko Test

$595.00

Positector 6000 Advanced Memory Body

$790.00