- Bargain Basement

- Abrasive Blasting

- Adhesion

- Ambient Conditions

- Cases

- Cathodic Protection

- Coating Test Panels

- Coating Thickness Gauge

- Combination Gauges

- Compliance Programs

- Concrete Testing

- Corrosion Coupon Test Kits

- Dry Film Thickness Gauges

- Field Microscopes

- Gloss & Appearance

- Hardness Testing

- Holiday/Pinhole Detection

- Inspection Instrument Kits

- Miscellaneous

- Moisture Detection

- Powder Coating

- Publications

- Surface Cleanliness

- Surface Contamination Test Kits

- Surface Profile

- Wall Thickness Gauges

- Wet Film Thickness Gauges

PosiTector RTR Replica Tape Reader

$425.00 – $1,200.00

Dial Depth Pit Gauge

$467.50

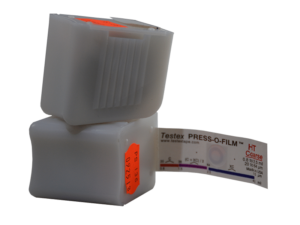

Testex Press-O-Film Replica Tape – Legacy Roll

$42.00

Testex replica tape is used in conjunction with an analog or digital spring-loaded micrometer for acquiring surface profile measurements according to Method C in ASTM D4417. The replica tape is rubbed onto the abrasive blast cleaned surface forming a reverse replica of the peak-valley pattern in the steel. The replica is quantified using a spring-loaded micrometer to determine the maximum peak-to-valley depth. Each roll of tape contains 50 pieces.

Coarse 0.8 to 2.5 / 20 to 64

X-Coarse 1.5 to 4.5 / 38 to 115

X-Coarse Plus 4.6 to 5.0 / 116 to 127

If you are looking for the new Testex cartons, click here.

SKU:

Testex Replica Tape

Categories: Best Sellers, DeFelsko Products, Surface Profile

Description

Testex Press-O-Film Replica Tape is used in conjunction with an analog or digital spring-loaded micrometer for acquiring surface profile measurements according to Method C in ASTM D4417. The replica tape is rubbed onto the abrasive blast cleaned surface forming a reverse replica of the peak-valley pattern in the steel. The replica is quantified using a spring-loaded micrometer to determine the maximum peak-to-valley depth. Grade (descriptive) Range When Used With Gauge (mils) / (um) Coarse 0.8 to 2.5 / 20 to 64 X-Coarse 1.5 to 4.5 / 38 to 115 X-Coarse Plus 4.6 to 5.0 / 116 to 127 Each roll of tape contains 50 pieces.

The impression can be studied in several ways:

- A simple micrometric dial thickness gage can be applied to the replica for field measurement of the average maximum peak-to-valley roughness, or “profile,” of a replicated surface, or,

- A digital thickness gage such as the PosiTector RTR can also field-measure profile and bridge the gap between tape grades by incorporating automatic linearization.

- An optical profiling interferometer or confocal microscope can be used in laboratory settings to produce maps of the replica’s surface topography. This is most appropriate to study of subtle features at the microinch (25 nanometers) level.

Additional information

| Brand |

Testex |

|---|

Related products

Keane-Tator Surface Profile Shot Comparator Disc 372/SH

$115.00

KTA NOG (Nozzle Orifice Gage)

NACE Surface Finish Weld Replica

$121.00

Based on NACE Standard RP0178, this 5.5" x11" visual comparator illustrates six degrees of surface finishing of lap welds and six degrees of surface finishing of butt welds. Two of the four corners on the comparator replicate a 1/8" and 1/4" radius for edge/corner grinding comparisons. Made in the USA.

PosiTector RTR 3D Replica Tape Reader Bundle

$50.00 – $1,995.00

PTC Durometers

$750.00 – $999.95

Measure the indention/penetration hardness of plastics, rubber and thick film coatings in the laboratory, shop or field according to ASTM D2240 using the PTC Durometer Hardness Tester.

Select optionsEarn up to 50 points.

This product has multiple variants. The options may be chosen on the product page

Testex Coarse Replica Tape (6-Pack)

$228.00

Testex X-Coarse Plus 4.6 to 5 mils (116 to 127 microns)

$42.00