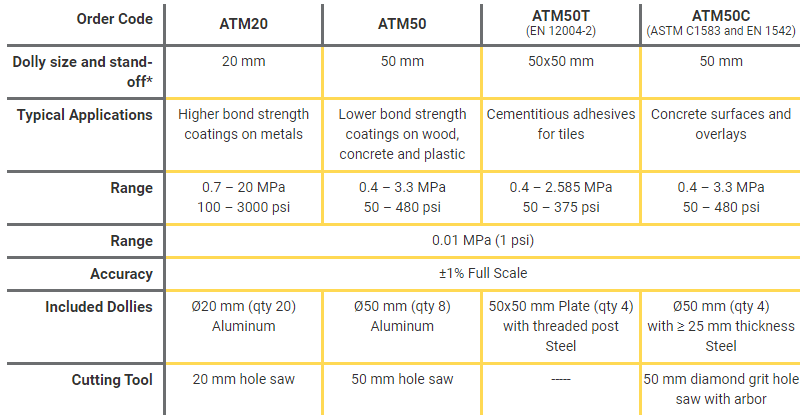

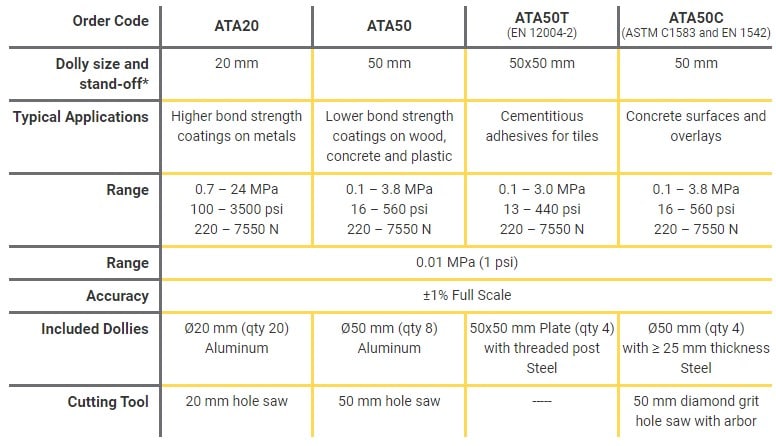

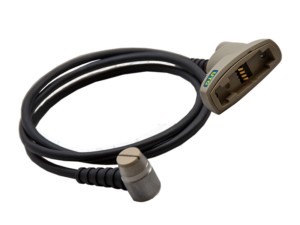

When utilized with a 50mm diameter dolly, the PosiTest AT is in a priming state until reaching a priming pressure of 16 psi. It is only after the priming pressure is reached that the instrument begins calculating and displaying the pull rate.

While it is possible to obtain readings below this priming pressure with the AT-M model, the AT-A automatic does not allow the operator to build priming pressure very slowly and is therefore not suitable for use below the priming pressure.

Note that all reported adhesion values (including those obtained below the priming pressure) are subject to the PosiTest AT gage’s full-scale accuracy of ± 1% (± 30 psi, AT-M; ± 35 psi, AT-A).